Ansheng Battery Market Research and Development Department: In recent years, with the rapid development of information and computer networks, my country's construction of data centers has been increasing. The smooth operation of the data center is inseparable from the guarantee of the UPS system. UPS system is also called "uninterruptible power supply", its function is to protect the uninterrupted power supply of the computer data center network equipment, and provide continuous power guarantee for the computer and its network system.

At present, in the construction of data centers in my country, most of the UPS systems use valve-regulated sealed lead-acid batteries (Ansheng brand valve-regulated sealed lead-acid batteries are the earliest domestic manufacturer of this type of battery) as the backup emergency power supply. Valve-regulated sealed lead-acid batteries have the characteristics of mature technology, high cost performance, convenient use and maintenance, mature production technology, environmentally friendly, and renewable. Among them, high-power lead-acid batteries also have high current output performance and high specific energy. The advantages are widely adopted. High-power lead-acid batteries are a key component of the UPS system, and their pros and cons directly affect the reliability of the UPS system (Ansheng battery reminder: the pros and cons are also reflected in the after-sales service system).

Ansheng Battery Quality Inspection Department found that among the many factors affecting UPS stability and reliability, battery leakage is the most fatal hidden danger that cannot be ignored. Once the battery leaks, causing an electrical short circuit in the battery pack, it will inevitably lead to an instantaneous drop in the output voltage of the UPS DC power supply system, causing the load equipment to lose power, causing network interruption and failure, affecting information communication transmission. If the power supply cannot be found and cut off in time, it will Cause a fire accident in the equipment room.

Ansheng battery research and development department analyzes the cause of leakage of domestic high-power lead-acid batteries

When the battery is used in the data room for a long time, no matter what type of battery, there will be more or less some safety hazards, such as manufacturing, handling, transportation, improper maintenance, long use time, poor installation, etc. Batteries are deformed and leaking, and battery leakage is a common safety hazard. Through years of research and analysis, the leakage is mainly caused by the following reasons.

1、Electrolyte

The high-power lead-acid battery is a maintenance-free battery, and there is no need to add electrolyte for later maintenance of the battery. In the production process, the lean solution technology is generally used. The oxygen generated by the positive electrode reaches the negative electrode through the ultra-fine glass fiber separator channel for composite absorption. If the amount of electrolyte in the battery is too much and the pressure increases, the composite channel is blocked, which will increase the interior of the battery. The gas pressure causes the battery to leak in the poorly sealed place.

2、Safety valve

The safety valve is a "metronome" for the battery to adjust the gas pressure. It can seal the battery under a certain pressure and prevent the electrolyte from overflowing to the outside world. When the battery exceeds the specified pressure, the safety valve automatically opens and deflates. Generally, there are two reasons for leakage of the safety valve:

One is that the amount of acid added to the battery is too much, the battery is in a state of rich liquid, which causes the gas channel for oxygen reification to be blocked, and the gas generated by the battery cannot be recombined. When the internal pressure increases, the safety valve is frequently opened, and the gas overflows the safety valve and is outside the battery. When cold, it will condense into acid around the safety valve;

The second is the aging of the rubber gasket around the safety valve and the change in battery sealing performance, which causes the valve opening pressure to drop. The safety valve is opened for a long time, and the acid mist is condensed into liquid, causing liquid leakage.

3、Pole terminal

The phenomenon of pole leakage is common in data centers. After one year of battery operation, individual pole terminals will leak. Often after five years of operation, the problem of pole terminal leakage is very serious. The key reason for battery leakage is that the post metal and the battery cover sealant are not properly matched. The post terminal is corroded by oxygen in an acidic environment. Under the action of the internal air pressure, the electrolyte flows along the corroded path to the surface of the terminal to cause leakage. Liquid, this is the phenomenon commonly known as climbing acid.

4、Battery compartment cover

Currently, there are two ways to seal the battery slot cover: epoxy resin sealing and heat sealing.

The leakage of epoxy resin seal is mainly because the seal control conditions are relatively strict. The epoxy resin formula and curing conditions are required to be well controlled, otherwise it will cause the sealant and the shell to bond poorly, forming a leakage channel and causing the battery Leakage;

Battery heat sealing is to heat and melt the battery cover plastic at a specific temperature and time. If the heating temperature and heating time are well controlled and the seal is clean and pollution-free, the seal is very reliable. Through anatomical analysis, the battery that generally leaks has honeycomb-shaped blisters in the hot melt layer of the battery tank cover. Under internal gas pressure, acid mist passes through the blisters with oxygen, resulting in leakage.

The preventive measures of Ansheng battery R&D department on high-power lead-acid battery leakage

To solve the problem of leakage of lead-acid battery packs, the most important thing is to ensure the quality of lead-acid batteries, such as ensuring that the amount of battery electrolyte is within a reasonable range, ensuring the tightness of the battery casing, and ensuring the effectiveness of the sealing of the battery slot cover Wait. Controlling leakage at the source is the most important way and the most basic responsibility of battery manufacturers.

Of course, it is difficult for any product to achieve a 100% yield. Therefore, it is of practical significance to prevent battery leakage from causing harm through some additional methods. Generally, data center users mainly take the following measures to prevent battery leakage from causing short circuit hazards.

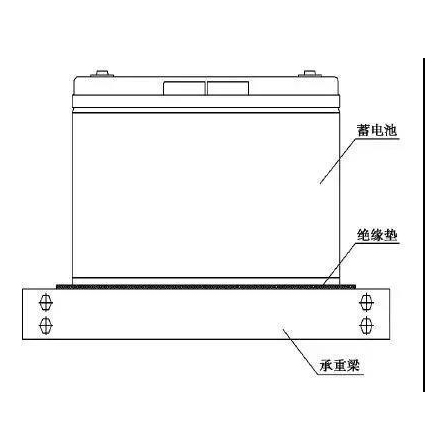

1、Insulation pad

The installation of insulating pads in data centers is the simplest and most effective way to prevent short circuits in high-power lead-acid batteries. It is generally placed between the battery and the load-bearing beam of the battery rack. By adding an insulating pad at the bottom of the battery, battery leakage occurs. The electrolyte is accumulated on the insulating pad, not on the battery rack, to prevent the corrosive liquid flowing out of the battery from leaking out and causing electrical shorts due to the conduction between the metal rack at the bottom of the battery. The installation diagram is shown in Figure 1.

This measure is convenient to implement and has a certain effect on the battery installed vertically, but it also has limitations: first, if the battery leaks a large amount, the insulating pad cannot completely absorb all the liquid, and the liquid flows to the lower shelf or battery, causing the shelf to corrode. And electrical short-circuit; second, when the battery is installed horizontally, because the insulating pad only covers part of the battery area, and cannot cover the battery cover and poles, the acid generated by battery leakage drips onto the lower battery and battery rack, causing the shelf Corrosion and electrical short-circuit; thirdly, the entire insulation pad is laid, which is not conducive to heat dissipation between upper and lower batteries.

Insulating pads currently have two materials: flame-retardant rubber pads and epoxy resin boards. The flame-retardant rubber pad is made of rubber, and flame retardant is added to the material to achieve the flame retardant effect. The rubber pad has high elasticity, so its seismic performance is particularly good; the rubber insulation pad has large surface resistance, difficult installation, and poor heat dissipation performance, but The price is relatively cheap.

The epoxy resin mat is made of epoxy board, also known as glass fiber cloth, which is made of epoxy resin and made by heating and high pressure. It has high mechanical performance at medium temperature and stable electrical performance under high humidity to prevent The electric short circuit caused by battery leakage is very effective. Relatively speaking, the epoxy insulating board has a smooth surface and is easy to install, but the price is more expensive than rubber pads.

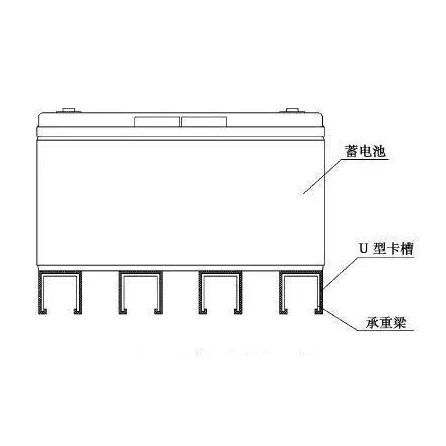

2、Insulation sheath

The contact part of each layer of the iron frame of the battery (load-bearing beam) and the battery shell is lined with a plastic insulating sheath to wrap the metal load-bearing beam, as shown in Figure 2, its function is to connect the battery to the metal battery frame It is separated from each other to prevent the leakage of corrosive liquid from connecting the battery and the rack and causing an electrical short circuit. The insulating sheath can also be called U-shaped slot or load-bearing beam sheath, and is generally designed to be U-shaped to be clamped on the battery load-bearing beam. The material is made of flame-retardant PVC, ABS or PP, which is smooth, wear-resistant, pressure resistant and easy to install. And does not affect the ventilation and heat dissipation of the upper and lower layers of the battery. The disadvantage is that it cannot accept liquid, and the amount of liquid will flow to the lower battery to cause corrosion. The insulating sheath needs to be customized with a plastic mold according to the shape of the load-bearing beam.

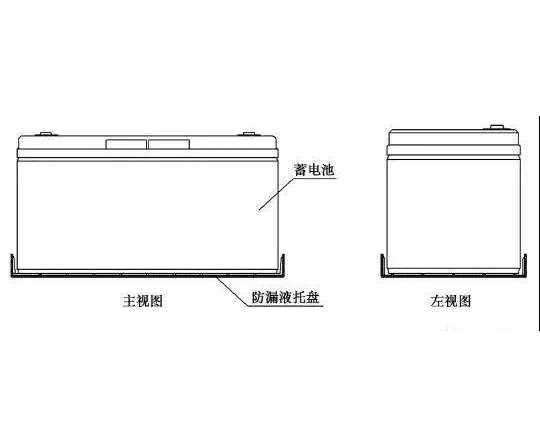

3、Anti-leakage tray

In order to prevent the corrosive liquid leaking from the battery from affecting other racks or batteries, a tray is designed at the bottom of the battery to fully support the entire battery. Its length and width are slightly larger than the length and width of the battery, and the acid leakage from the battery can follow the battery slot. The body flows into the leak-proof tray; the thickness of the tray is designed to have a certain strength to bear the weight of the battery; the bottom of the tray is designed with diversion ribs to spread the electrolyte to the tray, avoiding excessive electrolyte deposits in one place, and making the battery long-term Soaked in electrolyte; the tray material uses flame-retardant ABS or other flame-retardant plastic materials to ensure the flame-retardant performance of the tray and prevent the battery from burning due to electrical short circuit to a certain extent. The disadvantage is that the plastic mold must be customized for each type of battery. The installation diagram of the leak-proof tray is shown in Figure 3.

in conclusion

In recent years, domestic data room accidents caused by the leakage of lead-acid batteries are not uncommon, and the leakage has caused serious harm to the safe operation of the entire system. Therefore, in the daily maintenance of the data center computer room by Ansheng Battery R&D department over the years, it is very necessary to let everyone know the harm caused by the leakage of lead-acid battery, the cause and the countermeasures. This article analyzes the causes of lead-acid battery leakage in detail, and puts forward several preventive measures for battery leakage based on the situation that the battery leakage has formed, in order to provide some help to the safe operation of the data center.

|